191 MWdc / 210 MWh

storage installed capacity

Rain Lily Solar & Storage Project

Located on County Road 326, near Cleburne in Hood County, Texas, the Rain Lily Solar and Storage project is one of EE North America’s key projects in ERCOT.

The project is currently in development while finalizing environmental studies. Spanning approximately 810 acres, the land for the project has primarily been utilized for grazing purposes.

Development is scheduled to be completed by the end of 2026. Construction is scheduled to start near the end of 2027 with the first power being produced at the end of 2028.

Stay informed with updates, milestones, and community highlights from the Rain Lily Solar + Storage Project.

“Rain Lily Solar and Storage is a testament to EE North America’s commitment to advancing Texas’s energy future. This project combines solar power with battery storage to provide reliable, sustainable energy while reducing carbon emissions. We are proud to contribute to the economic development of Hood County and look forward to delivering long-term benefits for the community and the environment.”Michael Klein, Head of Project Development, US, EE North America

We selected this location based on a combination of factors including proximity to existing transmission infrastructure, solar resource quality, land availability and interest from landowners. Additionally, we conducted detailed environmental, cultural, and community assessments to ensure the site is suitable for long-term clean energy development.

Utility-scale solar refers to large solar power plants that generate electricity for the power grid, providing clean and renewable energy to homes, businesses, and industries. These power plants use solar photovoltaic (PV) panels to convert sunlight into electricity, which is then transmitted to the grid.

A utility-scale energy storage system is a facility designed to store electricity for use when demand is high. These systems improve grid stability, enhance reliability, and support the integration of renewable energy sources by storing excess electricity and delivering it when needed.

Utility-scale solar projects consist of rows of solar panels mounted on the ground, typically in areas with high solar exposure. These projects may also include tracking systems that allow the panels to follow the sun’s movement, maximizing energy generation throughout the day. Utility-scale energy storage projects typically consist of battery units housed in protective enclosures, similar in appearance to shipping containers, strategically placed near solar installations or grid infrastructure.

Solar energy complements conventional energy sources by supplying power during peak demand periods, such as hot summer afternoons when electricity use is high. When paired with energy storage, solar farms can provide reliable electricity even when the sun isn’t shining. Energy storage helps stabilize electricity prices by mitigating the variability in power supply and demand, reducing reliance on expensive peak-hour power generation.

Utility-scale solar and energy storage projects improve grid resilience, reduce power outages, and enhance the efficiency of renewable energy integration. These projects also generate tax revenue for local governments, funding infrastructure improvements and public services, and create jobs during construction and operation.

The Rain Lily project brings direct benefits to our community through tax revenue that supports local schools and services, job creation during construction and operation, lease payments to participating landowners, and potential partnerships with local educational and conservation initiatives.

The project will provide to support local services, schools, and infrastructure. This funding helps improve community resources and may reduce the tax burden on residents over time.

Studies across the U.S. show that utility-scale solar and energy storage projects do not negatively affect local property values. These projects are typically designed with visual screening and operate quietly, ensuring minimal impact on neighboring properties. In some cases, nearby properties have even seen value appreciation due to increased infrastructure investment in the area.

The electricity will first serve the local area through nearby transmission and distribution lines. Depending on grid needs, some of the energy may be routed to larger cities. But priority will be given to nearby communities and infrastructure.

The project is funded by private investors, including loans, equity, and federal tax credits. These federal incentives are common across all energy sectors, including oil, gas, nuclear, wind, and solar. Local taxes from the project will be paid directly to Hood County and local entities.

Most of the project spending stays local, covering jobs, equipment installation, operations, and community investment. While some components may come from global suppliers, we prioritize using U.S.-made equipment, materials, and services whenever possible.

A vegetative screening plan incorporating native trees and shrubs will be implemented to blend the project into the landscape. This ensures minimal visual impact while enhancing local native biodiversity.

No. The solar panels we use are designed with anti-reflective coating to absorb sunlight rather than reflect it. We also conducted glint and glare studies to ensure there is no impact on roadways and nearby residences.

The solar panels are mounted in rows, approximately 9–10 feet high, and will be surrounded by fencing and vegetation. We are working to preserve as much of the natural vegetation as possible and will use additional vegetative screening if needed to reduce visual impacts.

There will be minimal lighting at the project site and only for safety and security purposes. Any lights installed will be downward-facing and motion-activated. The facility is not staffed full-time and does not require overhead or street lighting.

Yes. The land underneath and surrounding the solar panels will be maintained using best practices such as native grass seeding and rotational mowing. We are exploring options for habitat restoration and pollinator-friendly ground cover to support biodiversity.

Yes. At the end of the project’s life, we are committed to fully decommissioning the site. This includes removing equipment, restoring the land, and recycling components where possible. Our land lease agreements and decommissioning plans ensure this commitment is upheld.

The project includes comprehensive wildlife protection measures such as establishing buffer zones around sensitive areas, adjusting construction timelines to avoid critical seasons, and preserving existing habitat. These steps follow environmental best practices and regulatory guidelines, ensuring we minimize disruption and support biodiversity throughout the project’s lifecycle.

Across Texas, warming trends and shifting environmental conditions are making it harder for many species to survive, by altering the habitats they depend on. Our utility-scale solar and energy storage project helps address these broader challenges by reducing the need for fossil fuels like natural gas, which are a key contributor to these changes. While any development has a footprint, the impact of this project is far smaller than the widespread disruptions being driven by emissions-intensive energy sources. By supporting clean energy, we’re contributing to a healthier, more sustainable environment for wildlife across the state.

The project prioritizes water resource protection by avoiding jurisdictional waterways, implementing erosion control measures, and ensuring sustainable land management practices.

Modern crystalline silicon (c-Si) solar panels are consistently characterized as non-hazardous under the EPA’s testing procedure which tests for leaching of toxic chemicals. Such testing creates conditions much more extreme than in the field: chopping up solar panels into tiny pieces, submerging them in an acidic solvent, then agitating them. Even in these extreme conditions, modern c-Si solar panels do not present a risk of leaching toxic chemicals or PFAS.[1] Testing consistently finds that the leachate concentrations of chemicals are far below the EPA’s allowable thresholds, therefore characterizing the solar panel leachates as non-hazardous, safe enough to be in sandboxes.

Less than a third of the 810-acre project footprint will be occupied by solar panels, batteries, and other equipment. The solar panel area will have open spaces for native grasses and pollinator habitat, and clearances for operations and maintenance. The battery area will be less than two acres, including open space for safety and service access. Final acreage figures will be posted on the website when they become available.

Yes, for safety and security reasons, the project will be enclosed with a fence. We are planning to use a fence that is non-obtrusive and blends in with the rural character of the area. The design will prioritize minimizing visual impact for neighbors.

The project will generate some minimal noise during construction, including typical construction activity and vehicles. Once the project is operational, there may be a low sound from the inverters and transformers during the daytime, which are not typically audible from nearby homes or roads. We conducted a noise study which determined that sound from the project equipment at the nearest residence will be quieter than a typical library and barely discernible.

A detailed visual assessment has been conducted to ensure that the project remains unobtrusive. Landscaping measures and careful site design further minimize visibility from surrounding communities.

Yes. The company is responsible for maintaining the project throughout its lifespan. This includes taking care of vegetation, keeping the fence in good condition, and ensuring that the site remains clean and safe.

The project is still in development, and final site design elements are being evaluated. Once plans are finalized and ready to be shared publicly, we will make appropriate documents available through public channels and forums.

The Rain Lily Solar & Storage project prioritizes fire safety through a comprehensive, multi-layered fire prevention and emergency response plan. This includes:

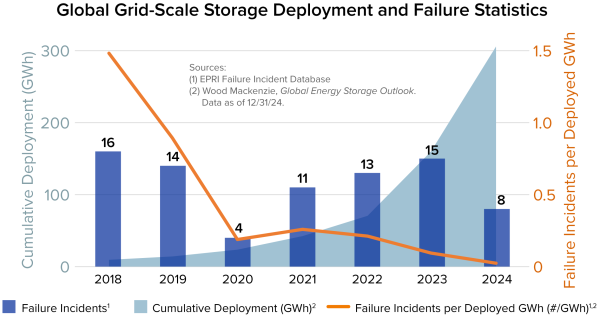

Yes, battery energy storage systems (BESS) have become dramatically safer as the industry has matured. The failure rate dropped by 98% from 2018 to 2024 as lessons learned from early failures have been incorporated into the latest designs and best practices, according to the Electric Power Research Institute (EPRI).

Source: EPRI

From September 2020 to September 2024, Texas’ total operational capacity of utility-scale batteries increased more than 4,100 percent to 5,707 megawatts (MW), while safety incidents have remained rare.

Key safety improvements include:

Rain Lily Project Safety Features:

Our battery energy storage system incorporates all current best practices and complies with stringent fire safety standards, including NFPA 855, UL 9540 & UL 9540A, UL 1973, and NFPA 68 & 69. The system undergoes rigorous third-party testing and engineering reviews to meet international safety certifications.

Texas/ERCOT Context:

ERCOT’s extensive battery deployment has proven beneficial for grid reliability, with BESS units generating $750 million in market savings during Winter Storm Heather in January 2024 by delivering critical grid services. When record hot temperatures strained the grid in September 2023, energy stored by BESS supplied electricity to approximately 434,000 homes and helped avoid grid failure.

Did you know?

On March 2, 2025, renewables collectively met a record 76% of ERCOT demand during peak conditions, demonstrating Texas’s leadership in clean energy transition. Wind and solar now provide approximately 30% of the state’s annual electricity generation.

Sources:

The battery energy storage system complies with the most stringent fire safety and reliability standards, including:

Additionally, our system undergoes rigorous third-party testing and engineering reviews to meet multiple international safety certifications, including standards for transportation, cybersecurity, and electrical components.

We recognize local community concerns about fire response times and are proactively working with local first responders and emergency services to address each of them. Our approach includes:

We are coordinating closely with local emergency responders to ensure they have the information, training, and tools needed to respond effectively in the unlikely event of an incident.

It is extremely rare. Solar panels are designed to withstand extreme weather and high temperatures. They are made with materials that are fire-resistant and follow strict national safety standards. We also use professional installation practices and include built-in fire prevention systems to ensure safety.

Yes. The Rain Lily Solar & Storage project meets or exceeds all national, state, and local safety regulations, ensuring compliance with fire protection codes and standards, environmental regulations, and operational reliability in accordance with industry best practices.

Specifically, the project:

While the final battery technology and vendor have not yet been selected, the project will use Lithium Iron Phosphate (LFP) chemistry, selected for high thermal stability and significantly reduced fire risk. All systems will be installed and operated in accordance with National Fire Protection Association (NFPA) standards and will include robust safety, fire prevention, and monitoring systems.

The project is led by an experienced team with a proven track record in developing, constructing, and operating utility-scale solar and energy storage projects. Our team works closely with regulatory agencies, fire safety consultants, third-party testing and certification experts, and battery energy storage system manufacturers to ensure the highest safety and performance standards. Additionally, our team has a demonstrated capability in navigating code compliance and ensuring long-term operational safety.

Yes. We are actively engaged with local emergency management and fire departments as part of our safety and permitting process. Community safety is our topmost priority.

Cybersecurity concerns are managed through a comprehensive, multi-layered strategy designed to safeguard both grid and facility operations. Key measures include:

Get in touch:

For any complaints, questions or queries on the project, reach out to our team on +1 737-203-7425 or info@eenorthamerica.com.